One of the most common errors that folks make in the delivery of energy and resource efficiency programs is to mistakenly set objectives to maximise the short term-returns from the program. The consequence of this approach can be disastrous for long-term value.

One of the most common errors that folks make in the delivery of energy and resource efficiency programs is to mistakenly set objectives to maximise the short term-returns from the program. The consequence of this approach can be disastrous for long-term value.

Some organisations take the view that the goal of the resource efficiency program is simply to optimise resource use in existing operations and managers will insist on a project-by-project justification with very rapid paybacks, leaving no room for the implementation of overarching continuous improvement systems. In other cases I have seen the program managers themselves get so carried away with the success and praise they receive that they become totally preoccupied with delivering the short-term savings as rapidly as possible and are reluctant to put in the effort to lay the foundations for longer-term success.

In either case there is a grave risk that at some point the “low hanging fruit” will exhausted, and the organisation will assume that there is little more to be done within the existing operations, victory will be declared and the program will come to an end. Unfortunately this outcome is surprisingly common, especially in programs where the primary emphasis has been on cost-reduction rather than on wider aspects of compliance, brand, risk or stakeholder engagement. In declaring victory these types of “flash in the pan” programs send an unwitting signal internally that resource efficiency is now complete and so accelerate the return to the “bad old ways” as behaviours revert and a cycle of value destruction begins.

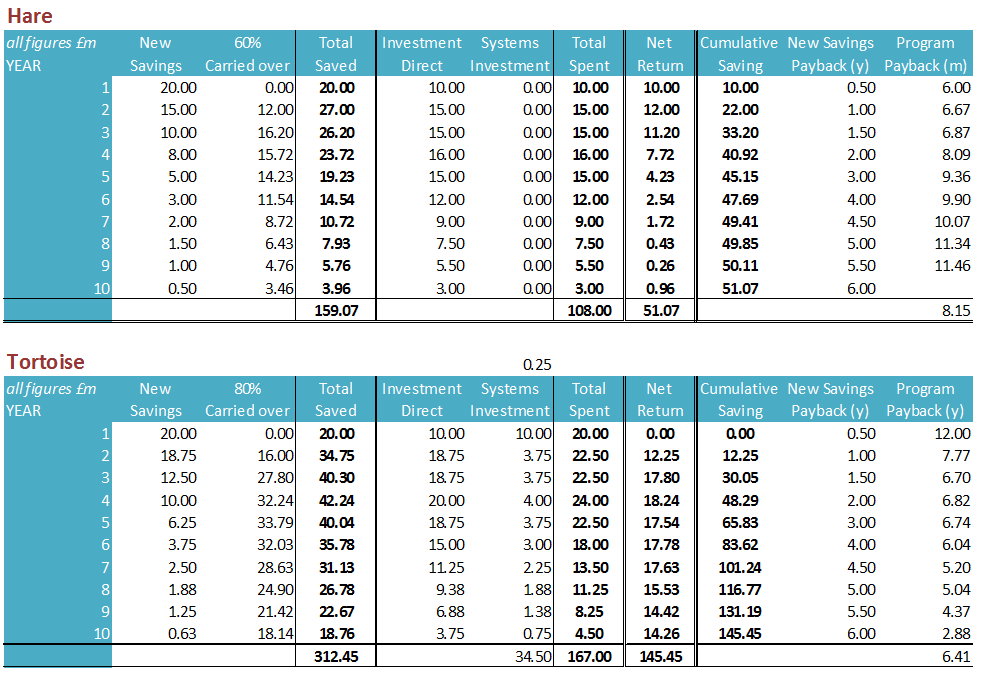

Not only is this poor practice but it undermines the value creation that we seek in out programs. We can illustrate this with a simple scenario comparing two different approaches to resource efficiency. Let us start by examining our first company Hare Corp. which has undertaken some initial discovery activities and established that there are some excellent opportunities to reduce operating costs through resource efficiency. Many of these £20m savings will come from no/low cost behavioural and maintenance changes so the initial payback is less than 6 months on an investment of £10m, creating a net saving of £10m in year one and winning praise for all involved. In year 2 the new savings are somewhat lower, £15m for an investment of £15m, giving a nevertheless attractive payback of 1 year. However as time passes the paybacks get longer and longer, fewer projects get funding, and the program profile starts to decline, so that by year 8 our program is now much reduced, adding only net £½m of savings. To all intents and purposes the program has lost momentum. At Hare Corp. the program has been driven to accelerate financial returns. Every project has been expected to meet a minimum payback so there has been little investment in sub-metering to monitor behavioural savings, and so only 60% of savings in any given year are maintained in the following year (if anything an optimistic figure in these circumstances). There has also been no investment in additional audits and studies to identify further projects, as this is seen to be an overhead that distract effort from implementing the existing opportunities.

The contrast in Tortoise plc. could not have been more different. Here the program managers have decided to put in place the systems to underpin continuous improvement from the outset. In particular they have argued that the first year savings should all be reinvested into the resource efficiency program – making available £10m to spend on appropriate sub-metering to provide feedback to users and teams on performance which means that 80% of savings identified in any given year are carried forwards to the next year, rather than Hare Corp’s 60%. Money was also spent on an “opportunities database” to systematically capture project opportunities and for external assistance to help evaluate these projects. The result of this was that each year Tortoise plc had 25% more projects to invest in than Hare Corp at the same payback rate. Of course all this additional effort around continuous improvement has a cost so Hare Corp has added 25% of the direct project investment each year from year 2 onwards into a “Systems Investment” pot to maintain the continuous improvement systems.

Figure 88 Illustration of two scenarios for resource efficiency, with and without the implementation of continuous improvement systems.

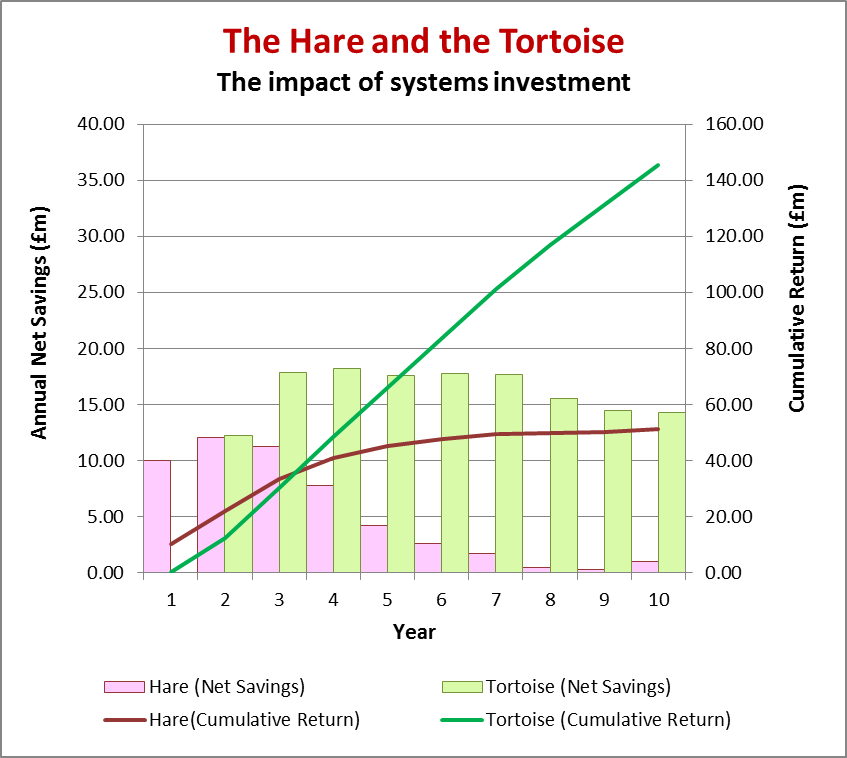

The table above shows the ten-year returns for each organisation. Despite the considerable additional costs entailed by the investments in continuous improvement systems (£34.5m), Tortoise plc. has done remarkably well compared to Hare Corp. For example we can see that at year 8, when Hare’s program was gasping its last breath, Tortoise plc. is delivering net annual savings of £15.5m and cumulative savings to this point are double Hare’s while the overall payback is more attractive. On every measure Tortoise is delivering more value than Hare.

Figure 89 – Graphical illustration of the benefits of investment in continuous improvement as part of a resource efficiency program.

Continuous improvement, far from being an unnecessary cost, substantially enhances the value of the resource efficiency program through three basic mechanisms:

- Opportunity availability: An improvement program ultimately depends on the availability of feasible interventions. Ideas for projects do not arise spontaneously. If there are no processes to replenish and evaluate these ideas then the program will run out of steam. A best practice resource efficiency program continually engages with resource users and experts to capture their ideas and to systematically evaluate them, usually using a tool called an opportunities database. In the scenario above Tortoise plc. has invested time and effort to encourage new ideas and to investigate these and so has 25% more project opportunities available in each year than Hare Corp., which leads to a significant cumulative increase in investments and hence savings.

- Opportunity return: The second source of additional value from continuous improvement approaches to resource efficiency lies in an increase in no/low cost opportunity identification. These are opportunities that arise from behaviour or control changes and are often only identified when resource users become engaged in eliminating sources of operational variability in resource use, through continuous improvement techniques like monitoring and targeting. The result is typically a large number of relative small projects whose aggregate savings are highly attractive and which decrease the overall payback of the program. In the case of the Hare and the Tortoise we have assumed that each year’s average payback is constant, so this effect has not been modelled in the table above.

- Savings conservation. Very few resource efficiency interventions (particularly the lower cost ones) are irreversible. Stepping down a thermostat in a building by 1 degree Centigrade will typically deliver 8% energy saving at no cost. However it is quite possible for people reverse this change and raise the temperature setting and so increase the energy use. Continuous improvement processes put measurement and reporting systems in place to ensure that once an intervention is made the change persists. In the scenario above Hare plc. only sustained 60% of savings from one year to the next, while Tortoise plc. was able to maintain 80% of saving year-on-year. This small difference cumulated to a big variance for the program.

It is important to note that the three effects above, opportunity availability, opportunity return and savings conservation reinforce each other. That is stating the obvious fact that if there are more, cheaper savings which will be maintained for longer the net return will increase. Small improvements in these three metrics can compound together to produce a large improvement in the overall program performance, and will usually offset the additional costs associated with implementing the continuous improvement systems many times over, as shown by the results of Tortoise plc.

In addition to the benefits of substantial additional value generation, the incorporation of continuous improvement methods into a resource efficiency program prepares the organisation to move beyond the optimisation of existing processes and start to contemplate how to transition to new business models and approaches that will dramatically transform the organisation.

0 Comments